The king is dead. Long live the king.

The basic chassis and propulsion system design that has served the car industry since its inception is about to go the way of all things. Less polluting electric vehicles are expected to become the norm going forward and like so many other things, science, physics and advanced technology have revealed one most efficient solution.

Rivian, the electric truck startup that just received $500 million from Ford calls its platform a ‘skateboard.’

Good name. Fits perfectly. It’s the same platform shape other new e-truck companies like Atlis, Workhorse and Bollinger use. And the same packaging design Faraday, Lucid, Porsche, Tesla and Volkswagen use, as well as Audi and Jaguar for their ICE (internal combustion engine)/EV hybrids.

You don’t need a college degree to understand weight should be carried as low as possible. The biggest and heaviest mass in an EV chassis is the battery pack, usually a group of lithium-ion (for now) cels that, not unlike flammable liquids, need to be protected from impact.

It simply can’t be anywhere other than within the frame rails, between the axles and underneath the driver or cargo load. That’s the one and only best option.

Over a century ago, when the automobile was invented, there were not a lot of platform choices either. The vehicle had to have an engine, usually at the front, close to a radiator, and a fuel tank, usually at the rear.

The image to the right is from 1937, showing an old truck sans body and bed that typifies most chassis designs from the late 1800s through Ferdinand Porsche’s ‘People’s Car” and then FWD and mid-engine vehicles. It reveals a big, heavy hunk of metal with lots of moving parts inside, connected via a driveshaft to a rear end to turn the rear wheels. It’s powered by combustible fuel stored in a tank.

Worked like a charm. And this basic platform spawned both sport and industry. Engines were swapped and boosted for performance, parts and equipment were developed and evolved. Something called the Hot Rod was born. Innovative enthusiasts, both in the garage and behind the wheel, proved their theories in competition, not a computer lab. They did it on dirt and paved oval tracks, road and street courses, drag strips, hill climbs, airport runways, dry lake beds and deserts.

That’s how cars and motorcycles created motorsports.

Now, here we are, at another precipice.

Is the ladder or spaceframe chassis holding an engine and fuel supply doomed?

Of course not. Cars that make noise and produce exhaust will be around for the foreseeable future; it’s just the ratio between those vehicles and ‘skateboard’ electric cars will eventually change. (Until as-yet undiscovered technologies like flux capacitors fueled by garbage, Dilithium crystals and Tylium to power starships, etc. make batteries and motors obsolete.)

One more thing to consider: How automobile racing will adapt to the platform evolution.

Well, let’s remember that as long as racing is a competition among human beings, the drivers sitting on-board and in control of their vehicles, their safety will always come first. That means some type of a safety cell or cage and roll over protection.

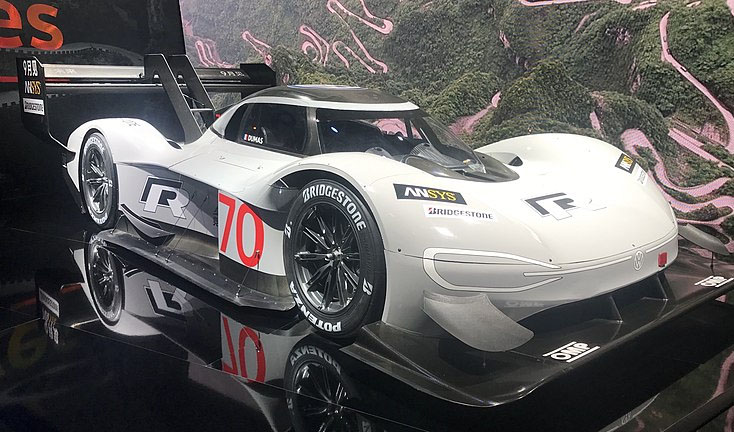

Shown here, a sports car prototype chassis that cost over a million to develop, with a longitudinal engine and gearbox behind the driver. The protection cage need not change if the engine, tranny and fuel cell are replaced by motors and a slab of batteries. It will still look like a race car.

And while we don’t really know what’s underneath the skin of the all-electric, Pikes Peak conquering Volkswagen I.D.R. race car, we can be sure of two things. The batteries and most the weight are as low as possible and driver safety is not compromised.

Form will always follow function. And the function of a race car is covering distance at the highest possible speed to finish ahead of the competition. So not to worry. We’ll ride out whatever changes occur in car design, propulsion, suspension and steering and just keep racing.

But be prepared. Change is definitely coming.